TQM / TCE – Énergir

SECTOR(S)

- Energy and civil works

LOCATION

Blainville, Québec

YEAR(S)

2020-2021

EXPERTISE

- Boilermaking

- Civil

- Fabrication

- Mechanical and Millwrithing

- Piping

- Structure steel

MANDATE

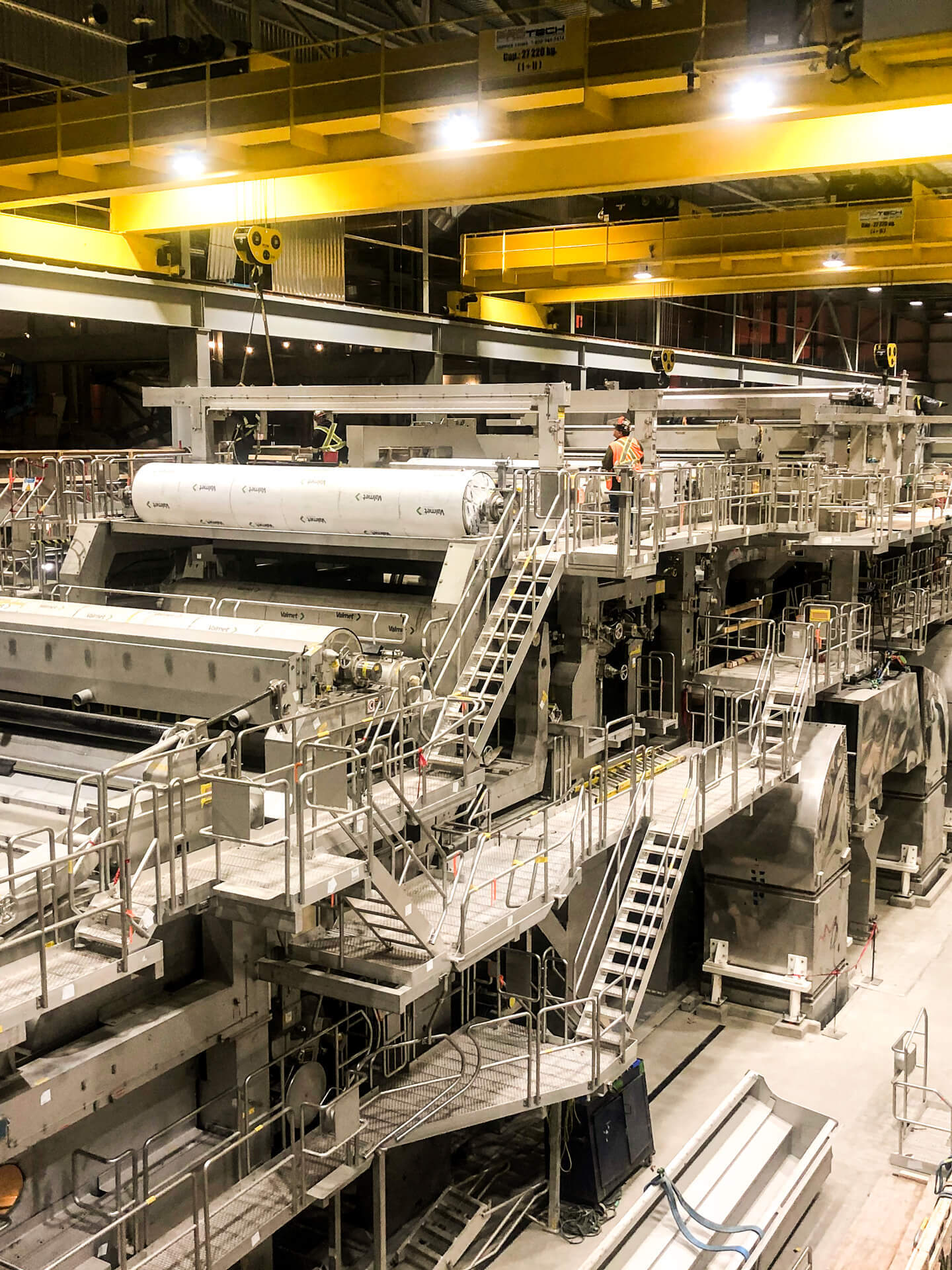

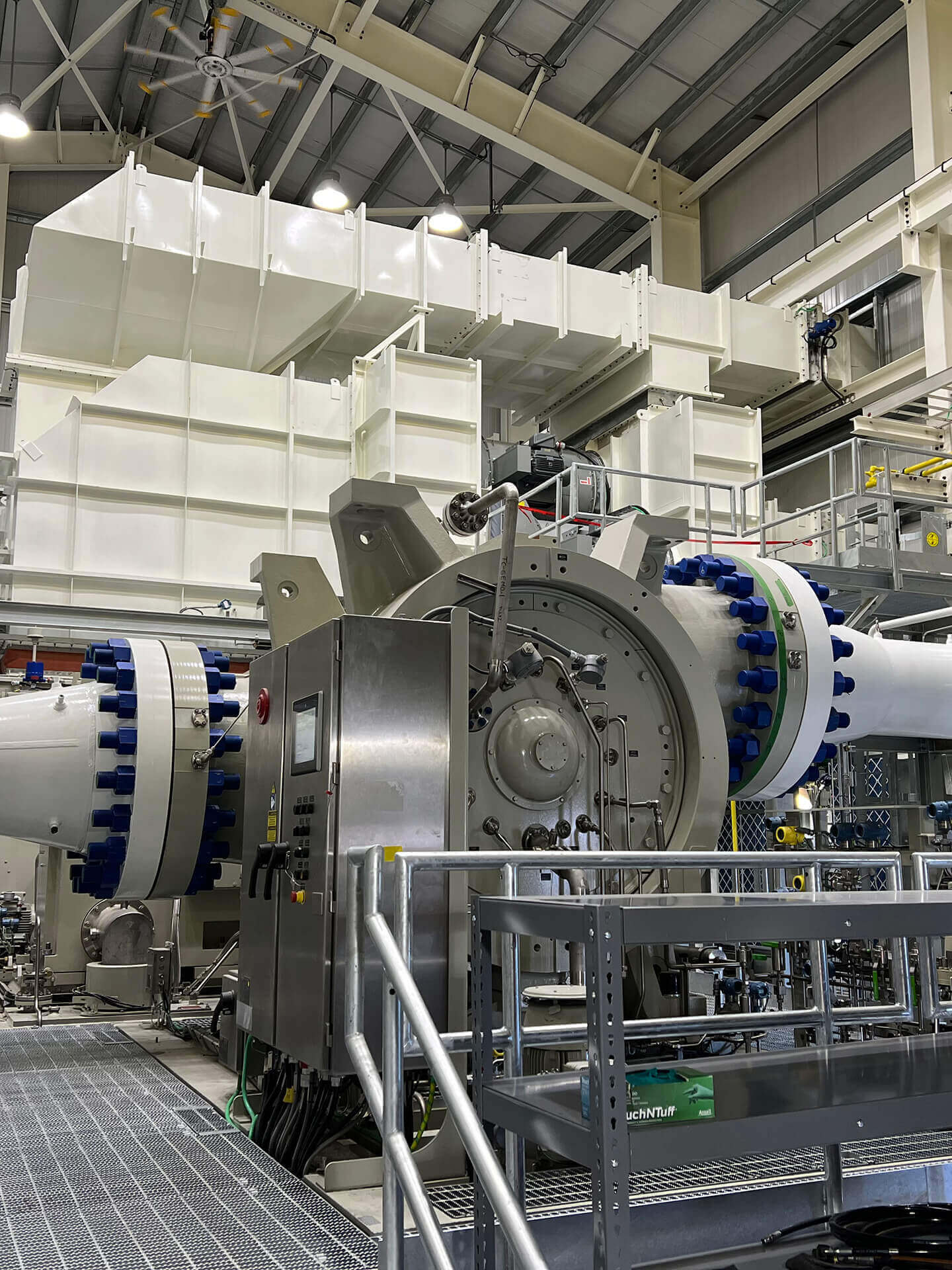

General contractor for the construction of a 48,000 m2 natural gas compressor station including one (1) 4 km access road and two (2) compressor packages including one (1) 19.4 MW electric turbine compressor package and one (1) 17.5 MW gas turbine compressor package.

In addition to the two compressor sets and their respective buildings, the station includes 5 auxiliary buildings as well as numerous pieces of equipment including two (2) suction scrubbers, one (1) air-cooled heat exchanger, one (1) VFD chiller and one (1) VFD transformer.

Specifically, the work included

the following items

- Health & safety and environmental management.

- Construction of a permanent four (4) km road – Construction of a 140-tonne permanent bridge.

- Installation of 192,000 m2 of cellular membrane (geogrid).

- Clearing and preparation of the site.

- Installation of 930 driven piles.

- Underground works.

- Pouring 1,250 m3 of concrete.

- Erecting seven (7) buildings.

- Pre-fabricating pressurised piping in the workshop.

- Installing underground and above-ground piping.

- Carrying out mechanical work.

- Carrying out electrical and instrumentation work.

- New 120 KV electrical input.

- Assistance with start-up and commissioning.

- Landscaping.

Our challenges

Key aspects of the project

- Environmental management.

- Geotechnical ground conditions requiring novel construction methods for the 4 km road and the surface of the new station.

- Completing access to the future site before the winter season to allow the delivery of aggregates and the construction of the future site.

- Site management at the heart of the pandemic period (COVID-19).

- Compliance with the works schedule compressed over fourteen (14) months.

- Compliance with budgets.

- Excavation and concrete work during the winter season.

- Transport of 375,000 tonnes of fill and stone.

- Ground support with sheet piling over 200 linear metres to allow connection to the TQM network without interrupting production (Stopple Bypass).

- Co-activity involving more than eight (8) cranes on site.

Innovative aspects of the project

- Project implementation based on the «constructability» approach upstream of construction.

- Carrying out the 4 km roadworks in two (2) phases, to facilitate construction of the site and delivery of the equipment. It would have been impossible to meet our deadline if the road had been built in a single phase.

- Soil support and water management with the installation of sheet piling over 200 linear metres for the tie-in of the network under optimum working conditions.

- A deadline of sixteen (16) working days, following the latest hydrostatic tests, to obtain authorization from the regulatory authorities for the commissioning of the station.

- Work to be carried out with respect for the surrounding community, limiting the noise and disruptive impacts that such activities can generate.

The site in figures

m2 of total surface area

workers at peak of the project

million of dollars in construction costs