TRT-ETGO – FELDA Global Venture (FGV)

SECTOR(S)

- Chemical and petrochemicals

LOCATION

Bécancour, Québec

YEAR(S)

Phase I : 2009-2010

and Phase II : 2011-2012

EXPERTISE

- Boilermaking

- Fabrication

- Mechanical and Millwrithing

- Piping

- Structure steel

MANDATE

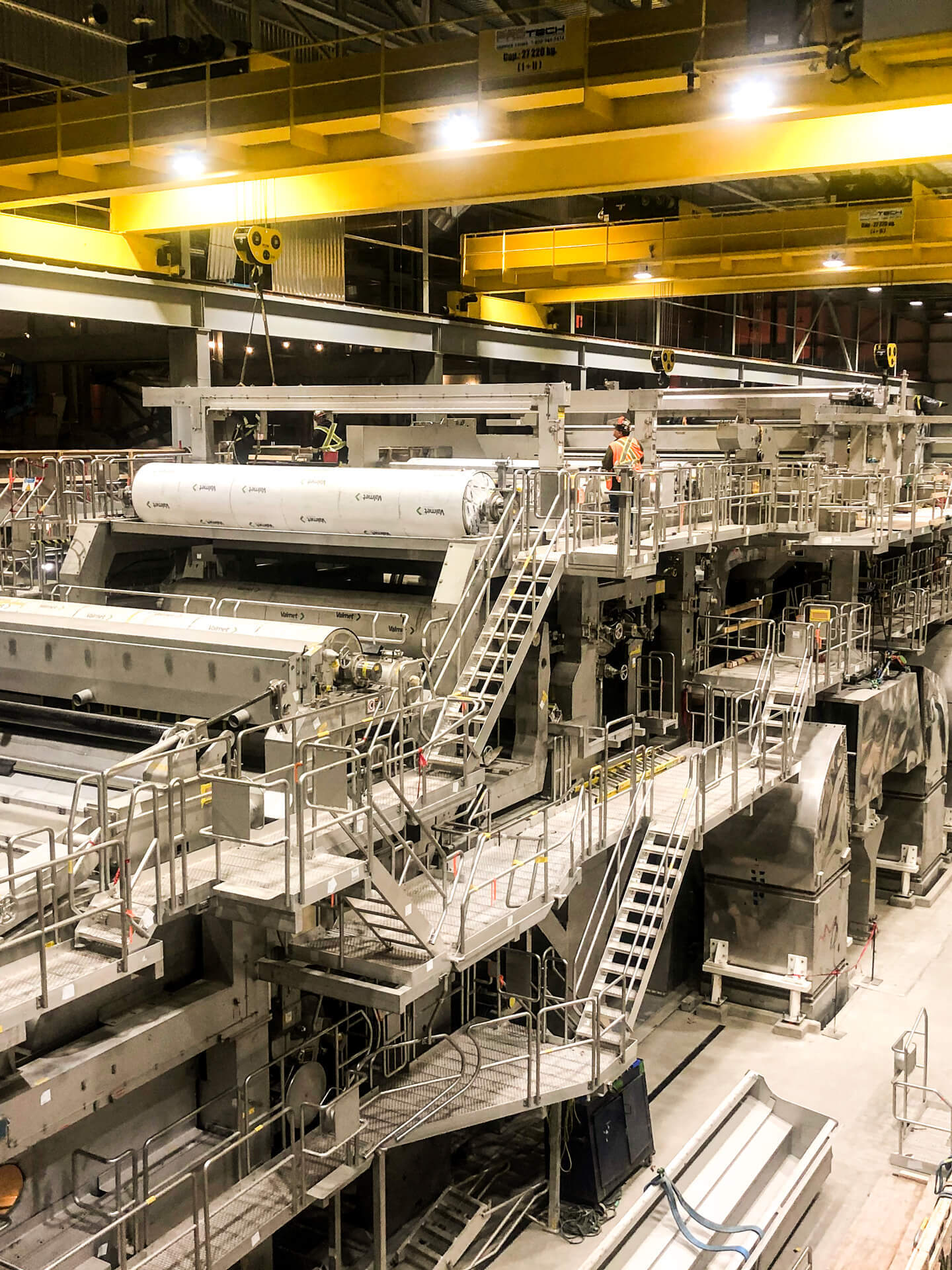

Prime mechanical contractor for the construction of a green field soybean and canola oil production plant. Specifically, the work included the following:

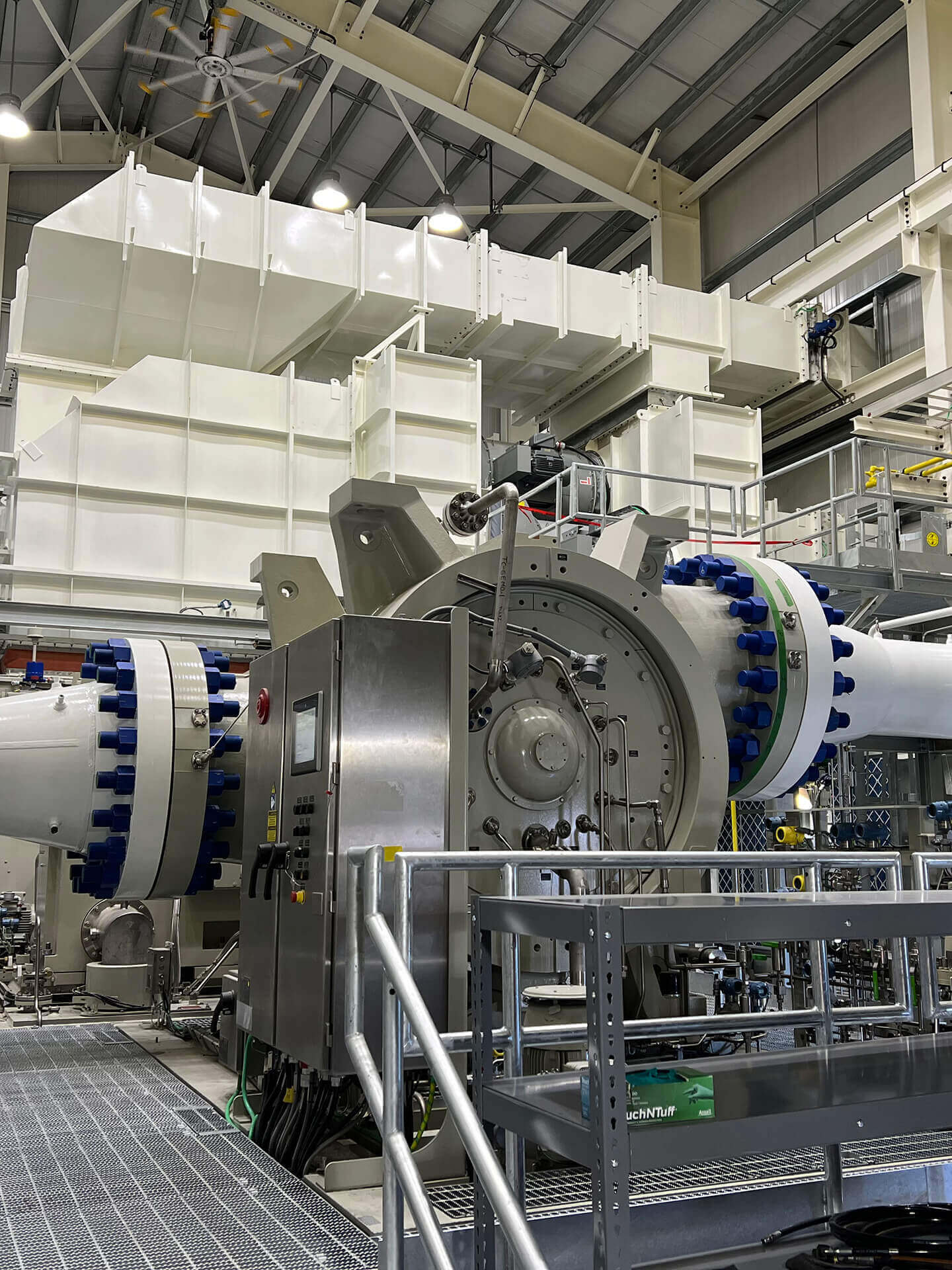

- Handling and transportation of forty-two (42) major pieces of equipment from Malaysia. The equipments was delivered to the port of Bécancour.

- Installation of all mechanical process equipments, i.e. over three hundred and seventy-five (375) equipments in the preparation, extraction and refining sectors.

- Fabrication and installation of piping in the preparation and refining sectors, totaling over 25,000 linear feet of piping.

- Installation of 190 conveyors, towers and bridges totalizing over 5,400 linear ft of conveyors and 242 miscellaneous chutes/transfers.

- Supply and installation of seven miscellaneous storage tanks, including 4 tanks of 45 m in diameter.

- Design, prefabrication and installation of all interconnection ducts and chutes between equipments, as well as various soybean and canola dust removal systems for the preparation and refining sectors, representing over 18,000 linear ft of ductwork.

- Assembly and erection of the grain dryer.

Our challenges

Project highlights

- Handling and special transport from the port of Bécancour to the installation site.

- Installation of major equipments simultaneously with erection of the steel structure of the 3 main buildings.

- Critical lifting operations (major equipments, tandem lifts, modular sections, etc.).

- Installation of all exterior equipments on piles.

- Design and conception of all gravity chutes between equipments.

- Fabrication and installation of all gravity chutes between equipments.

- Numerous prefabrications on site.

- Work during winter.

- Significant co-activity in each sector.

- Numerous overlapping jobs.

- Work schedule compressed to fourteen (14) months.

- On budget.

Innovative aspects of the project

- Numerous on-site prefabrications.

- Technical team integrated with process specialists from the Malaysian Felda Group.

- Multi-disciplinary execution team.

- Joint contractual agreement covering commissioning, start-up and optimization of production processes, as well as maintenance of the various production sectors.

The site in figures

0

workers at peak

0

process equipments installed during the project

0

million of dollars in construction costs.